Pool tied to building.

Often architects specifying indoor pools will place the pool hard up against one wall with the wall of the building running into the pool. While aesthetically pleasing this opens up a can of worms with regards to the integrity of the pool structure. Settling of the foundations or movement in the building can result in water loss from the pool shell due to the stress involved. It is also impossible to access any services located behind this wall, for example pool lights, return inlets etc. The recommended method in this instance is to locate the pool 350mm from the building that is enough for a coping stone and allows access if required. The pool can then be constructed independently of the building and allow movement in both structures.

If the Look of a wall hard up against the building is required its recommended a false wall be constructed to allow for this construction.

Insulation

The majority of heat loss from a swimming pool, up to 85 – 90% in fact, is through the surface. This can be dramatically reduced by covering the surface when not in use. This will reduce evaporation and therefore reduce cooling and running costs.

There are several types of cover available ranging from liquid to “plastic bubble”; from slatted to tarpaulin type sheet; from manual to electric to hydraulically operated (see section on ‘Covering’ in previous section under Outdoor Pools for more detail on cover systems).

Since the introduction of Part L of the Building Regulations pertaining specifically to indoor pools (see next section), it has been mandatory to insulate the pool walls and floors. There are proprietary products for swimming pools and other water retaining structures which typically manufactured of closed cell polystyrene with very high compressive strength to withstand the considerable load imposed by the weight of the pool shell and the water. The insulation boards are fitted between the wall or floor and the backfill.

Although insulating the shell is only mandatory (at the moment) in indoor pool installations, it would be good practice and beneficial in minimising heat losses in outdoor pools.

Building Regulations – Part L

Part L of the Building Regulations (Conservation of Fuel & Power, Approved Document L1B) came into force on 1st October 2010. Swimming pools are referred to twice in this document. Firstly the heat retention capability, or U value, of the pool shell structure should be equal to or less than 0.25 watts per m²K. Generally a concrete structure would have to have incredibly thick walls and floor to achieve this. The principle usually adopted is to sheath the shell in sufficient insulation material, fit to be used underground and with an appropriate crushing strength, to achieve the required figure. Secondly when the heat retention capability of the building is calculated, the pool hall floor calculation should ignore the pool but include the pool footprint as the same material as the rest of that floor.

A Compass Pool achived this using a combination of Ceramic Insulators within the Laminate. Backed by a sprayed polyurethane layer with an extruded polystyrene (XPS) under the floor. This has many advantages as you are not heating a thermal mass of concrete and there are no gaps for cold bridging.

Currently only indoor pools have to have shell insulation according to this Regulation and outdoor pools remain unaffected, however many customers are choosing it as an option.

Wherever possible, an automatic pool cover should be used to minimise evaporation losses when the pool is not being used. Using a cover will also allow the air temperature to be reduced by reducing the air heating “set point”. If a cover is in place then evaporation will be controlled and hence the air temperature need not be maintained at 1oC above water temperature.

With a system which does utilise a cover, two air temperature settings would normally be referred to as having two modes of operation.

• Occupied, when the pool cover is removed and the pool is in use and the air temperature is raised to the “occupied set point”

• Unoccupied, when the pool cover is in place over the water surface and the air temperature is dropped to the unoccupied setting, normally known as the “set back” temperature.

The “set back” temperature would normally be of the order of 21oC allowing the air heating to be shut off some 6oC earlier than the typical “occupied” condition of 30oC.

With modern highly insulated buildings it is very likely that the room air temperature may not drop as expected when the cover is put in place, and the air heating is turned down. The heat loss from the pool, through the pool cover, may well be sufficient to keep the room air warm, even when the air heating has been turned off using the “set back” system.

Air temperatures staying above the set back temperature are sometimes wrongly interpreted as the system malfunctioning. Generally it is the heat loss through the pool cover that is responsible, coupled with the high thermal performance of the building.

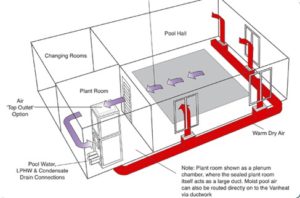

Air distribution

The only satisfactory way of keeping a pool hall at the correct air temperature and humidity is by forced air movement. Convection using domestic radiators will not work.

The air can be directed around the pool hall either by extract fans operating on humidistats and discharging humid air out of the pool hall and drawing in fresh air from the outside, or by recirculating the air via an air handling unit which also heats and de-humidifies the air. This unit can either blow the air into the pool hall in a haphazard way and pull it back into itself, or it can distribute it via a ducting system and return it back via another.

The use of a ducting system allows the warm air to be directed to areas where condensation is likely to occur which are usually glazed areas.

Ducting

Two main options for ducting exist for pools, either on budget systems a simple blow suck design can be implemented pulled air in and expelling from one location. This system can however leave condensation on glass areas. A full ducted system is recommended for most situations blowing air to areas of glass and sky lights.

Ducting will either be positioned in the floor or in a dropped bulk head around the ceiling.

Pool Lighting

The water in the pool can only be illuminated by underwater lights. The surrounding illumination either indoors or outdoors will not do the job.

Equally fibre optics generally only provide pinpoint light and not the floodlight required. The can be used to great effect to highlight steps etc.

There are many effective underwater light types on the market. The sealed beam and halogen types are still available, but are now being superseded my more versatile, energy efficient and longer lamp-life LED lighting systems. These systems offer greater output and are typical multicoloured, with the home owner being able to pick a colour to convey a particular mood or ambience; or can set the lights to a cycle which phases through a range of colours, or is even synchronised with music.