If a swimming pool is to be used throughout the year the structure placed over a it must conform to Building Regulations Part L (Conservation of Fuel & Power, Approved Document L1B). If the structure does not conform, then heating systems will not be permitted to heat that structure. Heating the water will be permitted. However as the ambient external temperature drops and with it the internal temperature, condensation will be formed by the difference in temperature between the water and air. Fogging will occur to the extent that visibility will be almost nil and the bathers will be cold when the are out of the water. In effect bathing will stop but the swimming season will be extended.

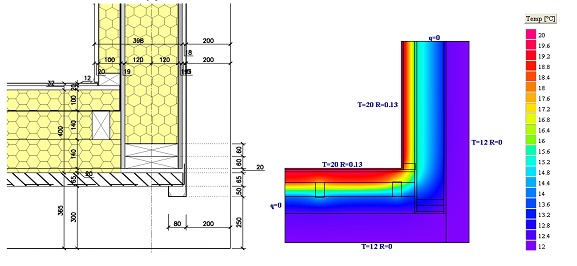

Consequently most indoor pools are of a traditional build. The following paragraphs give some guidance notes. However, it should be noted that even with the best environmental control, power failures with the cover off the pool can result in condensation forming. Condensation will form when air in the pool hall at 28oC comes into contact with anything at approximately 21oC; this is “cold bridging”. Steelwork in the structure of the building should be insulated to prevent this happening in voids.

Pool Hall Air temperature

Having established the required water temperature, the air temperature will normally be set at 1oC higher for the design of the environmental control system. Thus for an indoor pool whose water is to be heated to 29oC, the air would normally be heated to 30oC. This practice allows a degree of natural control of water evaporation and will reduce both the equipment required and the running costs of the system. It should be understood that this practice is not essential, and it is possible to design a system where the air is cooler than the water. Unless specifically stated otherwise all designers would assume that the scheme is to be designed with the air warmer than the pool water.

Vapour Control

The air within the pool hall needs to be contained within the hall. In other words the hall needs to be sealed with vapour barriers either in the horizontal plane, vertical plane or both. Those barriers must not be compromised either when being set in place or when other fixtures or fittings are installed. Doors and windows should be air sealed; it is good practise to have an air lock of two doors if the pool hall opens directly into the dwelling or others areas at lower temperature.

Surface Finishes

Generally speaking the internal finishes of the pool hall should be “external” type materials; that which you would use on the outside of the building.

Plaster / Plasterboard are not recommended for use in pool halls, Please see knauf aquapannels or lafarge gtec aqua board

Stretch Ceilings

A Stretch Ceiling is a suspended ceiling system consisting of two basic components – a perimeter track and lightweight fabric membrane which stretches and clips into the track. In addition to ceilings the system can be used for wall coverings, light diffusers and creative shapes. Stretch Ceilings allow the incorporation of all types of light fixtures, grilles and fixing points by the use of a proprietary background support. The stretch fabric material is suitable to install in all types of swimming pool environments. Stretch ceilings offer increased light reflection, improved acoustics, attractive decorative finishes and a maintenance free, water impermeable ceiling that will not require any ongoing decoration.

Flooring / Surround

The type and style of the surround, and therefore choice of materials, will be largely dictated by the aesthetic desires of your client. However, bear in mind that the area will be wet for a lot of the time, but subject to areas of high traffic, so selecting non-slip materials designed for such areas is important. A pendulum slip test is recommended to certify its slip resistance. All Compass pools products include this as standard. In addition to traditional finishes such as tile and stone, there are also synthetic flooring finishes specifically designed for such wet areas which are attractive, practical and kind on bathers’ feet.

Water based underfloor heating is an attractive option with bare feet.

Glazing

Double or triple glazing should always be used. Solar gain may have a tendency to increase the pool hall temperature above that which is acceptable The only way to counter that is to ensure the air handling system incorporates an air cooling or air changing facility.

Where recessed windows, glazing bars or bell lights are used it is important to address the air distribution from the ducting accordingly.

Where aluminium glazing is specified the inside out the outside face should be split so as not to create a cold bridge and condensation. The same applies to handles on doors both internal and external.

Pool Hall Lighting

The lighting in the pool hall must be installed according to Electrical Regulations and a general comment, including power outlet, is that all with 2.5 metres of the water, in any plane should be SELV. With a minimum rating of IP55.

It is also good practise to put lighting in positions which are easily accessible and not over the pool.

Pool hall lighting will not illuminate the water, and suitable underwater lighting must be specified and fitted.

Changing & Toilets

These rooms, and indeed any occupied by bathers within the pool hall, will have to be ventilated in the same way and with the same system as the pool hall. Changing in a cold room is not pleasant and the room will, eventually, be covered in mould. As previously stated the use of radiators in these room will not provide the air movement required.

The ducting system should incorporate sprigs into these areas to blow air into or draw air out of them. Consequently the door should not be of the sealed type.

Splash out Handling

It is inevitable that water will either be splashed out of the pool or taken out in soaking bathing costumes. The fall on the surround should be to a gully drain around the perimeter of the pool hall in the case of a freeboard pool; or back to the overflow channel in the case of a deck level pool.

Vertical splash tiles at the bottom of the walls at the joint of the floor are useful. Floor tiles should either be non-slip, or treated with an anti-slip application.

Service Considerations

All electrical work must be carried out by a registered, competent Electrician working to BS7671 “Requirements for Electrical Installations” including the Document “Special Locations 7”. The Swimming Pool and Allied Trades Association also consider that all electrical equipment installed in the pool plant room should be to IP55 as there is a risk of spray contamination.

Particular attention should be made to the material electrical fittings are made from where exposed. Plastics are prefered but, where required, stainless steel switches should be of 316 grade treated stainless.

All gas installations should be carried out to “Gas Safety (Installation and Use) Regulations 1998 by an Operative with the appropriate HWB 1 qualification.

All water supplies must be carried out to “Water Supply (Water Fittings) Regulations 1999 in particular any topping-up device connection must have an air gap. All Compass Pools comply to this as standard.